What we can do at Shimura Seiki

What we can do because of Shimura Seiki

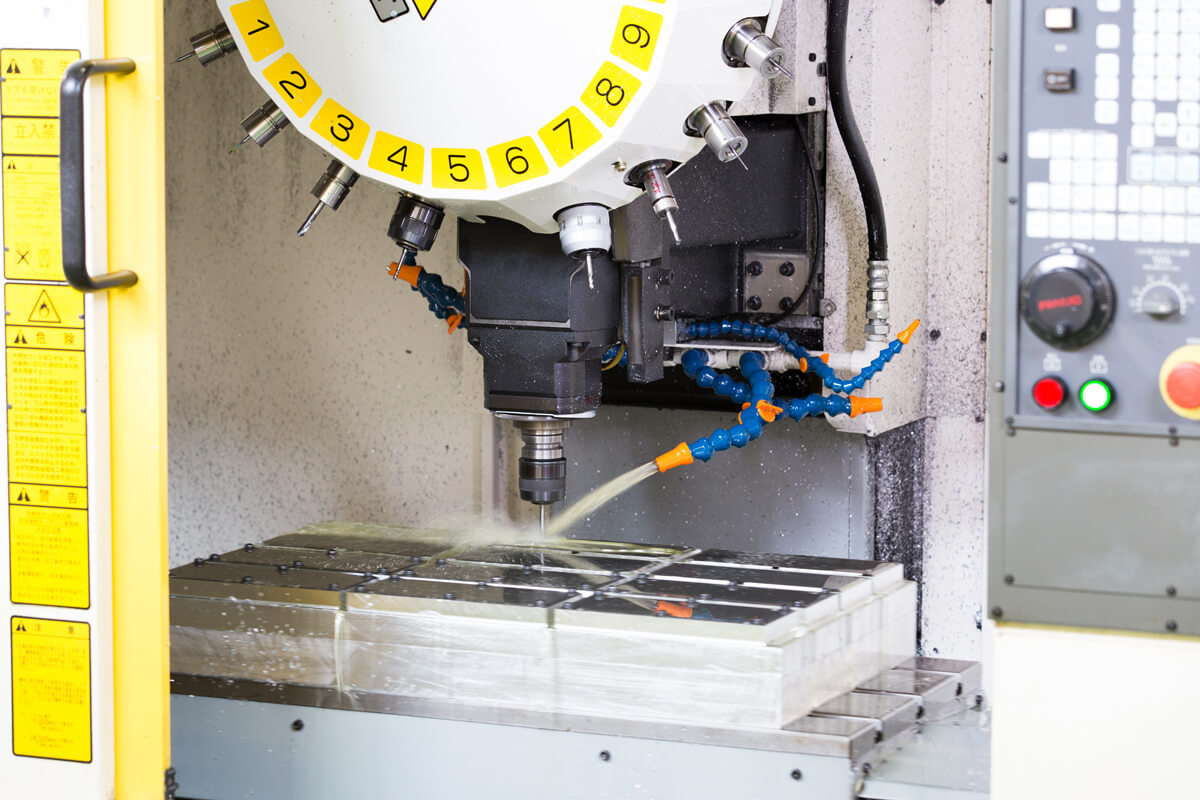

Precision Machining of Shimura Seiki

We put our heart and soul into each and every part that you request.

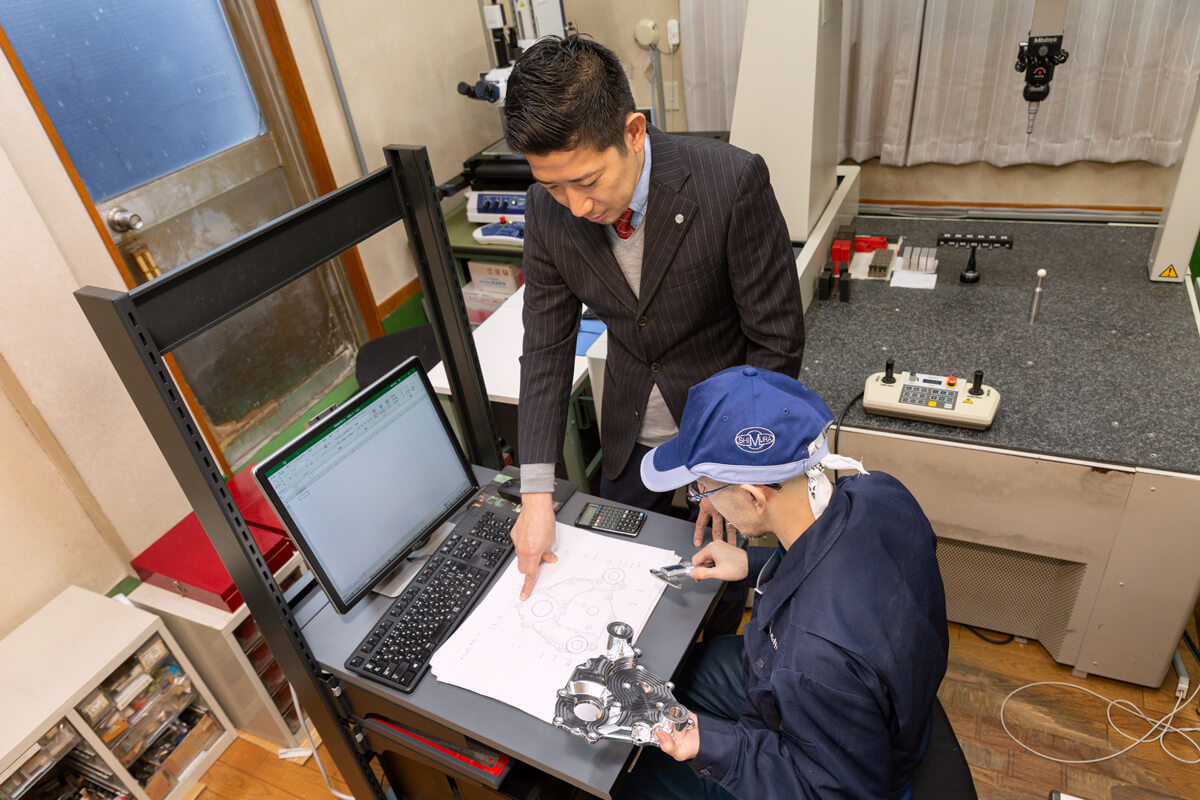

In order to deliver parts that satisfy our customers, we have a system in place for each department.

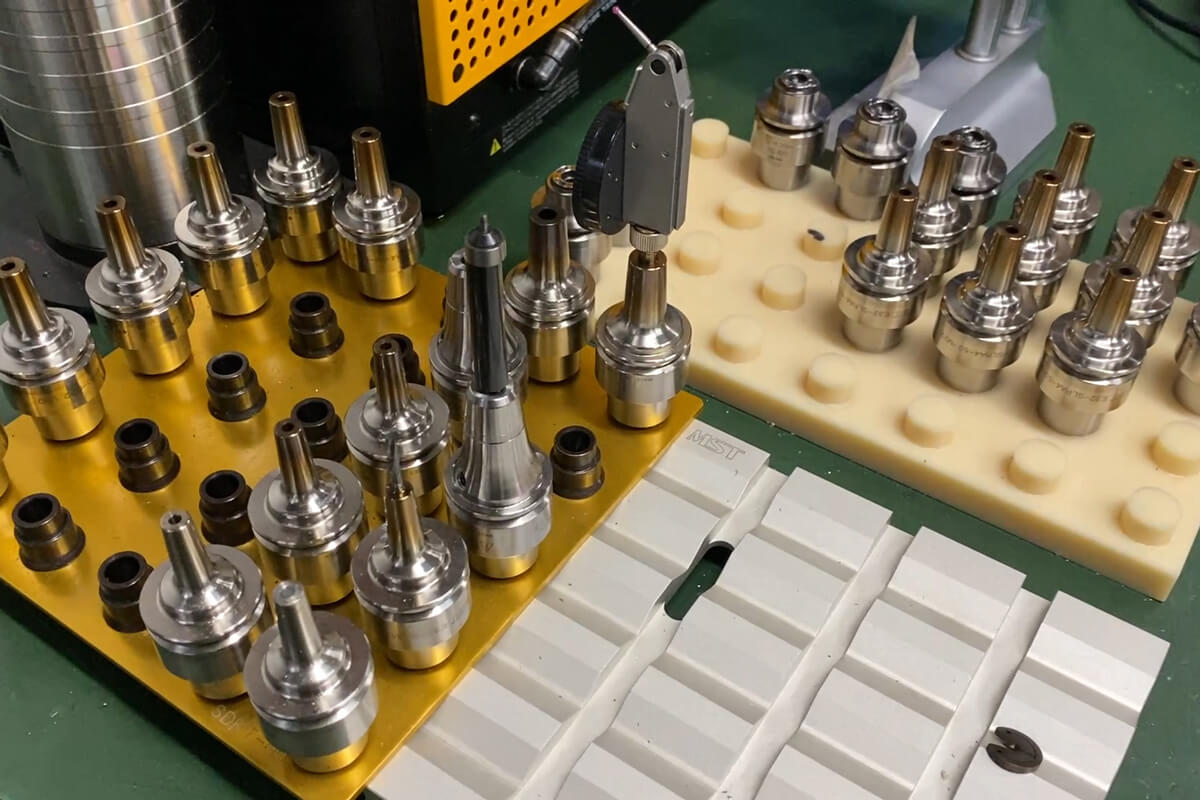

The number of facilities and production control systems that can handle a wide variety of products in small lots with short delivery times as well as mass production.

In addition, the company has the technology and equipment to handle everything from micromachining to large-scale processing.

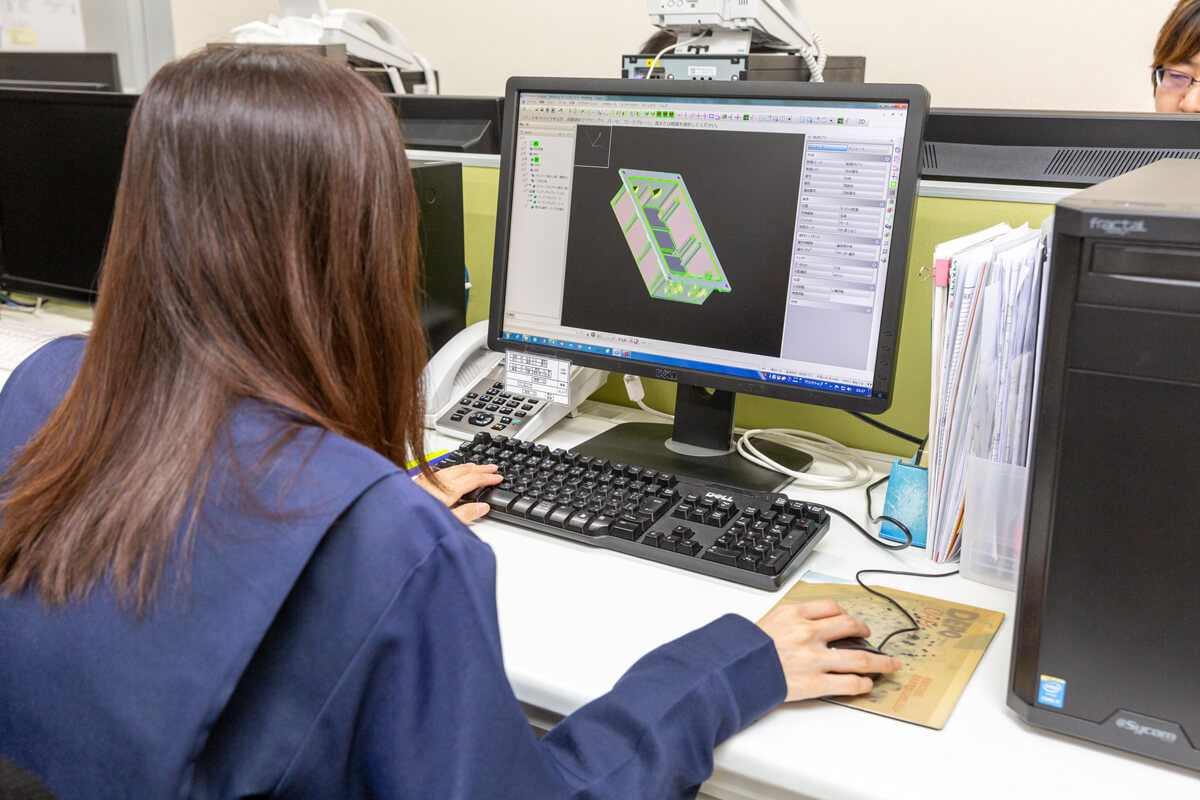

In addition to production from drawings, the company is capable of integrated production from sketching of idea products to design, processing, and delivery.

Shimura’s precision processing technology enables us to deliver products that are the best of both worlds.

Metal

| Aluminum | A2011 / A2024 / A5052 / A6061 / A7075 / ADC12 etc |

|---|---|

| Stainless steel | SUS303 / SUS304 / SUS316 / SUS440C / SUS430 / SUS630 etc |

| Titanium | Ti6Al4V / TB340 etc |

| copper | C3604(brass) / C1011 / C1020 etc |

| Iron | SS400 / S50C etc |

| Magnesium | AZ91 etc |

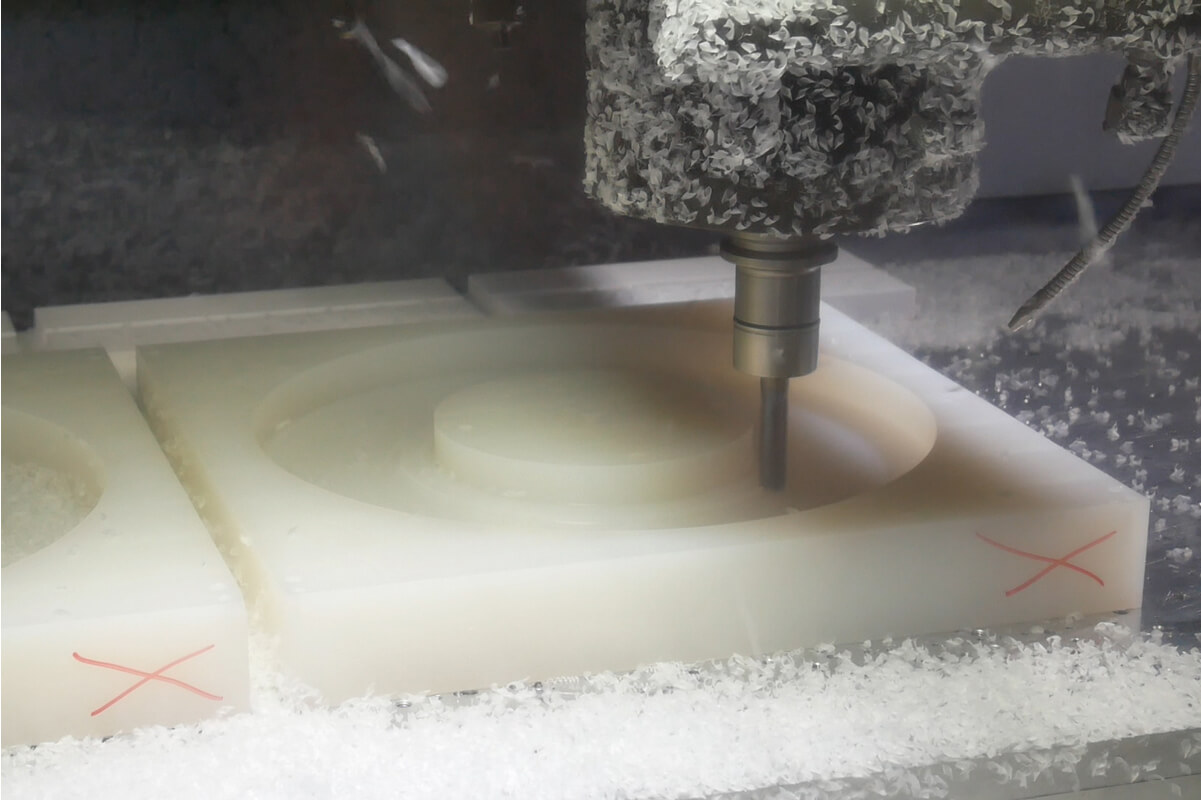

Resin

- ABC

- POM

- PPS

- PBT

- PES

- PC

- PA

- PEEK

- PP

- Norill

- Unirate

- With various types of glass

Reasons for Precision Machining of Shimura Seiki

Reasons for Precision Machining

of Shimura Seiki

Enclosure parts and mechanical parts (resin) for copy and fax machines, etc.

Exterior and mechanical parts of SLR cameras (resin)

Metal parts related to office machines

Manufacture of exterior and mechanical parts of reflex cameras and aperture focus parts

Endoscope-related parts (SUS, resin)

Laparoscope-related parts (SUS-based)

Metal and plastic parts for medical devices

Exterior parts around engine

Parts around transmission (metal)

Watch exterior parts

Mechanical parts (metal, plastic)

Processing of parts related to semiconductor equipment (metal and resin)

Manufacture of medical device components

Equipment-related manufacturing

Manufacture of in-house products

Supporting manufacturing in each of Japan’s leading industries

We have a solid track record in these demanding and precise genres

-

1

Precision processing

We can meet the strictest requirements in terms of law, geometric tolerance, angle, surface roughness, and burr removal.

We meet the high-precision demands of our customers with a wide range of processing technologies for both resin and metal. -

-

2

Micro fabrication

We can handle not only shape processing but also parts processing, mirror surface processing, fine groove processing, and fine hole processing that require high surface accuracy by using small diameter tools of φ0.1.

-

-

3

Machining difficult

We can process titanium, chromium molybdenum, inconel, and tungsten, which are considered difficult-to-cut materials.

-

-

4

Additional processing

Our production facilities are capable of mass production with precision processing of die-cast products and follow-up processing of resin molded products.

It is less costly than rebuilding from scratch and can shorten the delivery time. -

-

5

Research & Devel

We are involved in research and development for customers throughout Japan and overseas, and are capable of planning, developing, designing, manufacturing, and assembling a variety of products, from product devices to simple jigs and tools.

-

-

6

Quality assurance

We will continue to develop as a reliable company by guaranteeing high-precision parts through inspections using three-dimensional measuring instruments, measuring microscopes, and various gauges, as well as thorough quality control.

-

-

7

New normal

We can provide you with a quote on the same day, and meetings can be held online.

We will realize “monozukuri” that meets the needs of the new normal era. -

Home

Home