Shimura Seiki can do it

We are proud of this responsiveness

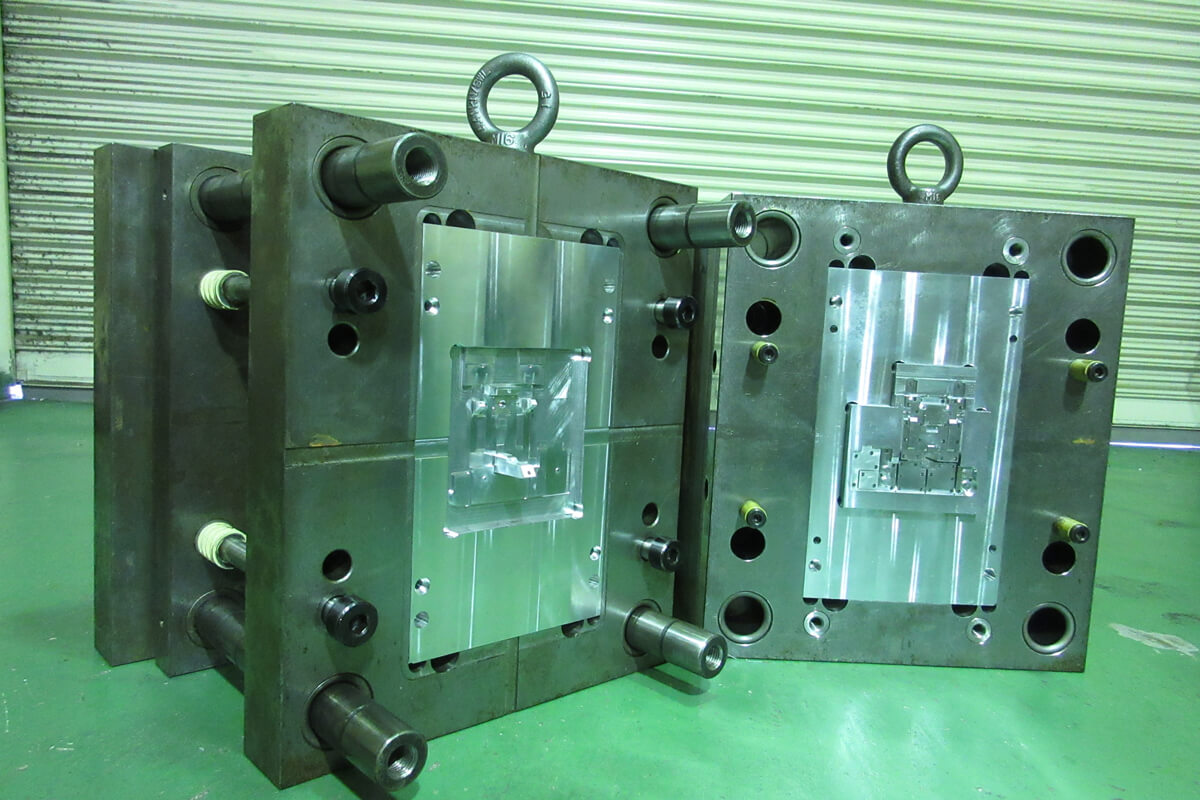

Shimura Injection Molding and Prototype Molds

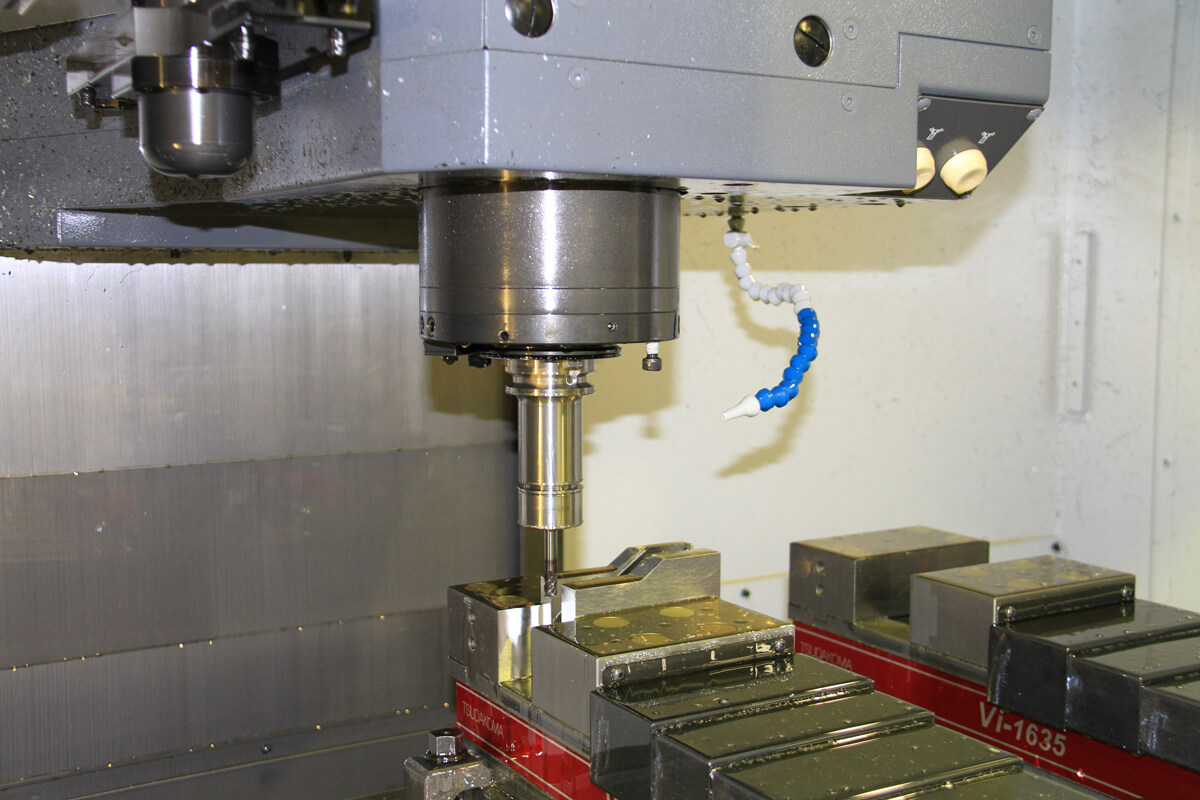

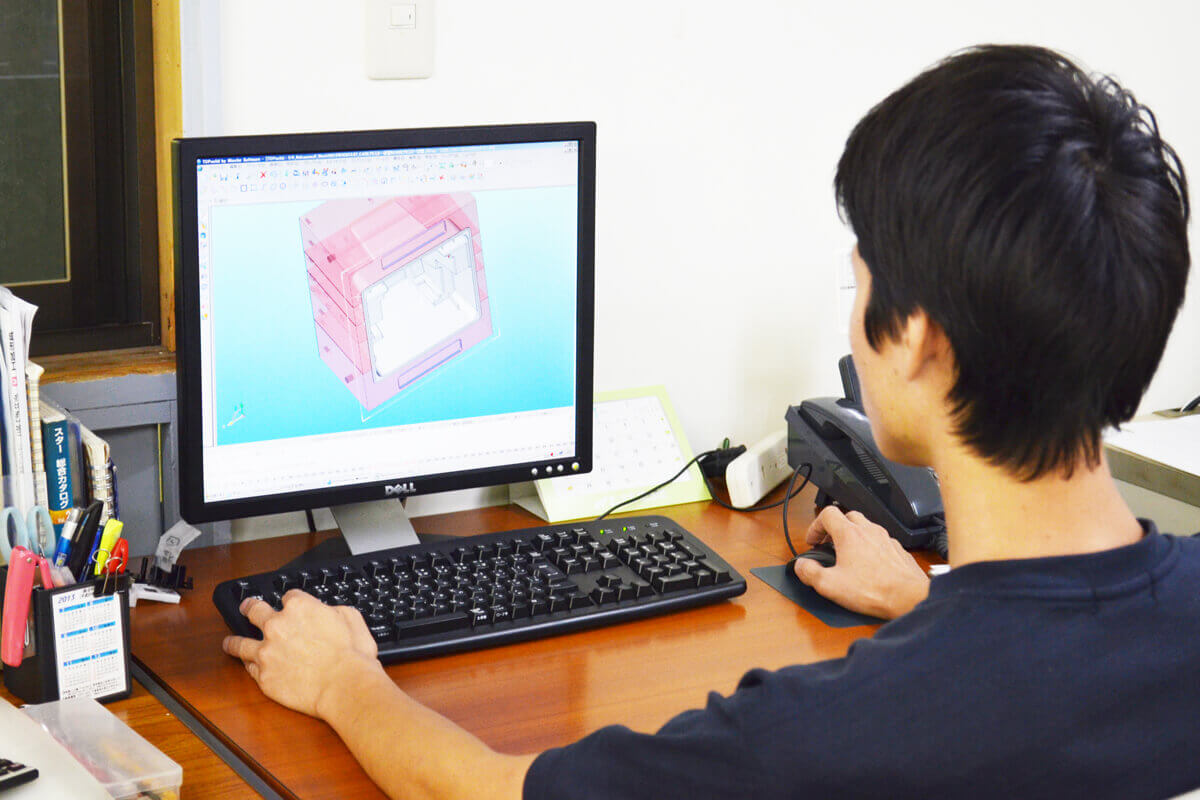

Shimura Seiki offers an integrated service from mold design and fabrication to machining.

We can produce and ship anywhere from 50 to 10,000 custom parts to meet your needs.

Our design support engineers will respond to your quotation within 24 hours and propose how we can efficiently manufacture your products. We will realize “small lot”, “low cost”, and “quick delivery” of injection molding dies used for products in various industries such as automobile, electric, IT, food, cosmetics, pharmaceutical, medical equipment, and other miscellaneous goods, which are made possible by Shimura’s precision processing technology.

Reasons for Precision Machining of Shimura Seiki

Reasons for Precision Machining

of Shimura Seiki

Enclosure parts and mechanical parts (resin) for copy and fax machines, etc.

Exterior and mechanical parts of SLR cameras (resin)

Metal parts related to office machines

Manufacture of exterior and mechanical parts of reflex cameras and aperture focus parts

Endoscope-related parts (SUS, resin)

Laparoscope-related parts (SUS-based)

Metal and plastic parts for medical devices

Exterior parts around engine

Parts around transmission (metal)

Watch exterior parts

Mechanical parts (metal, plastic)

Processing of parts related to semiconductor equipment (metal and resin)

Manufacture of medical device components

Equipment-related manufacturing

Manufacture of in-house products

Supporting manufacturing in each of Japan’s leading industries

We have a solid track record in these demanding and precise genres

-

1

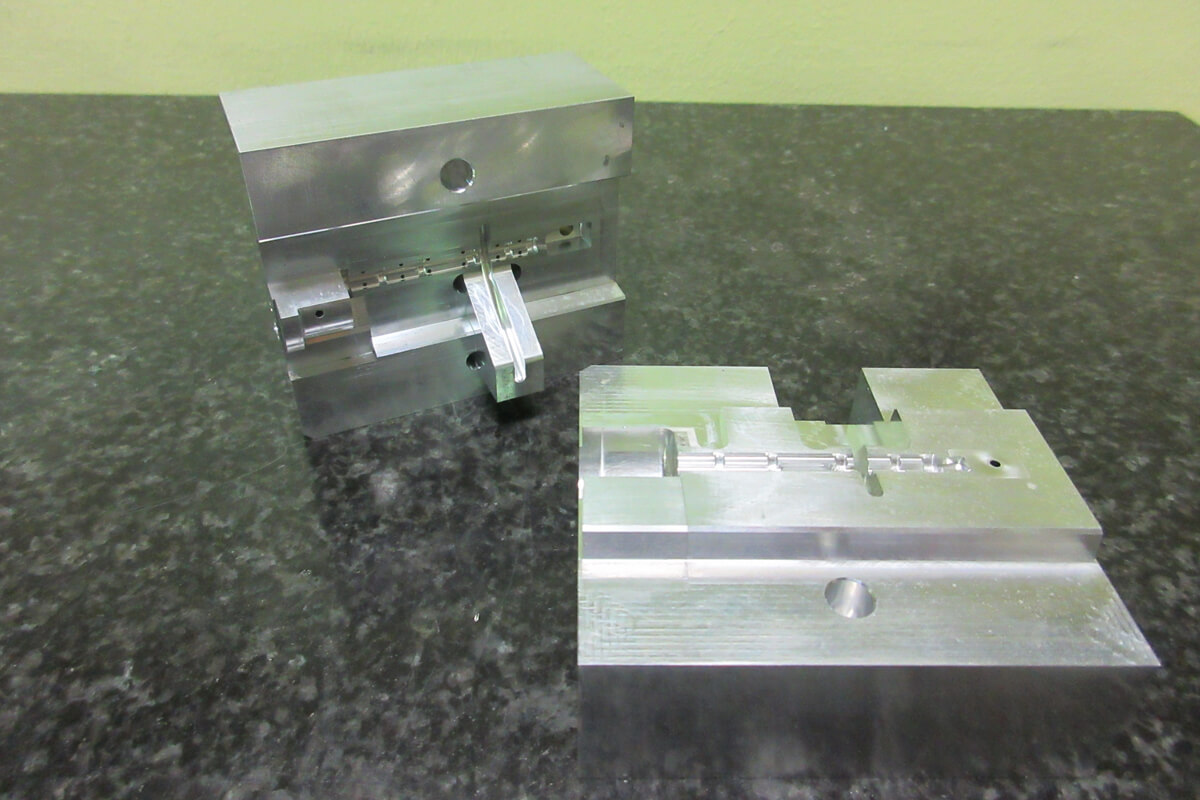

Prototype mold

Prototype molds will be made of aluminum alloy to reduce costs.

The optimal number of molded products is 50 to 10,000. -

-

2

Quick delivery

Minimum delivery time is 7 to 10 days. (Delivery time depends on the shape.)

The use of cassette type aluminum alloy molds optimizes the process and reduces the time required for manufacturing. -

-

3

Low cost

Our design support engineers will advise you on how to manufacture your product more efficiently and provide you with a quote within 24 hours.

In addition, our expertise and experience in resin flow, shrinkage, and mold structure will allow us to make better proposals. -

-

4

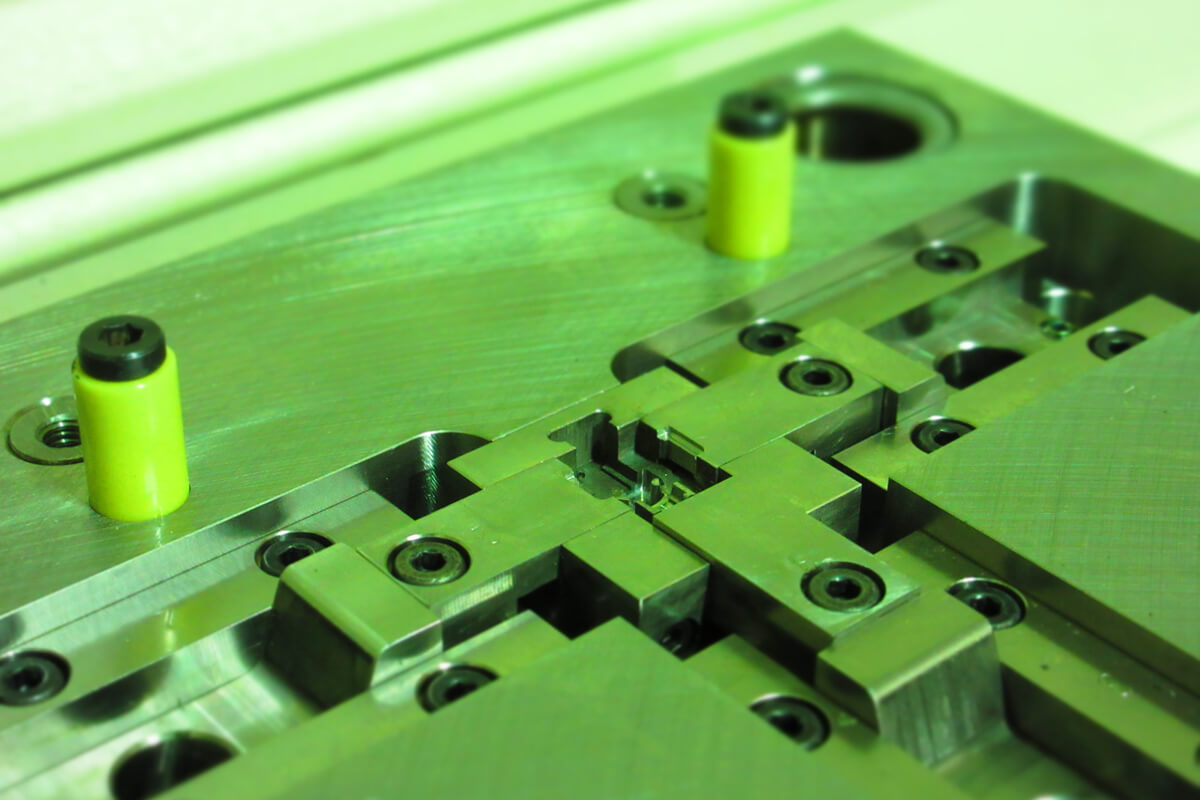

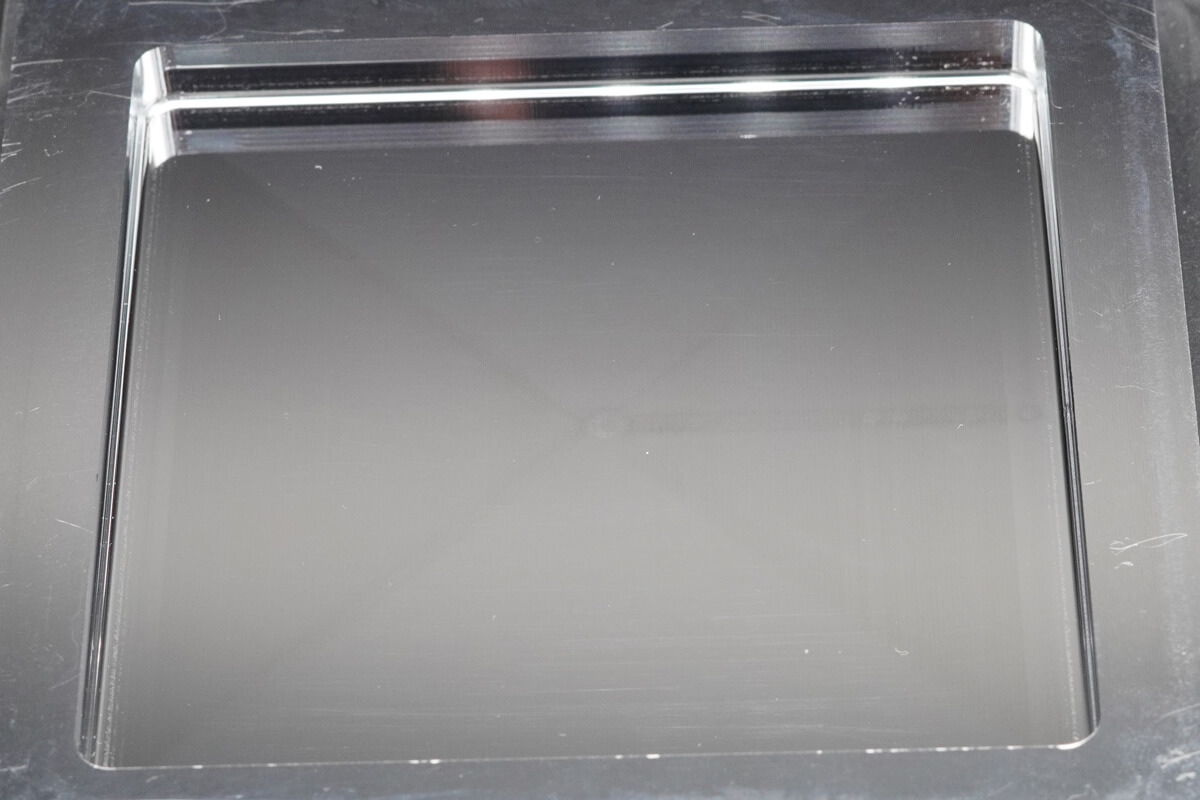

Polishing less

By replacing manual polishing with machine processing in the production of molds for products that require mirror finishing, it is possible to shorten delivery times and minimize costs.

-

Home

Home